Drako Platform Architecture

Unified. Real-time. Scalable.

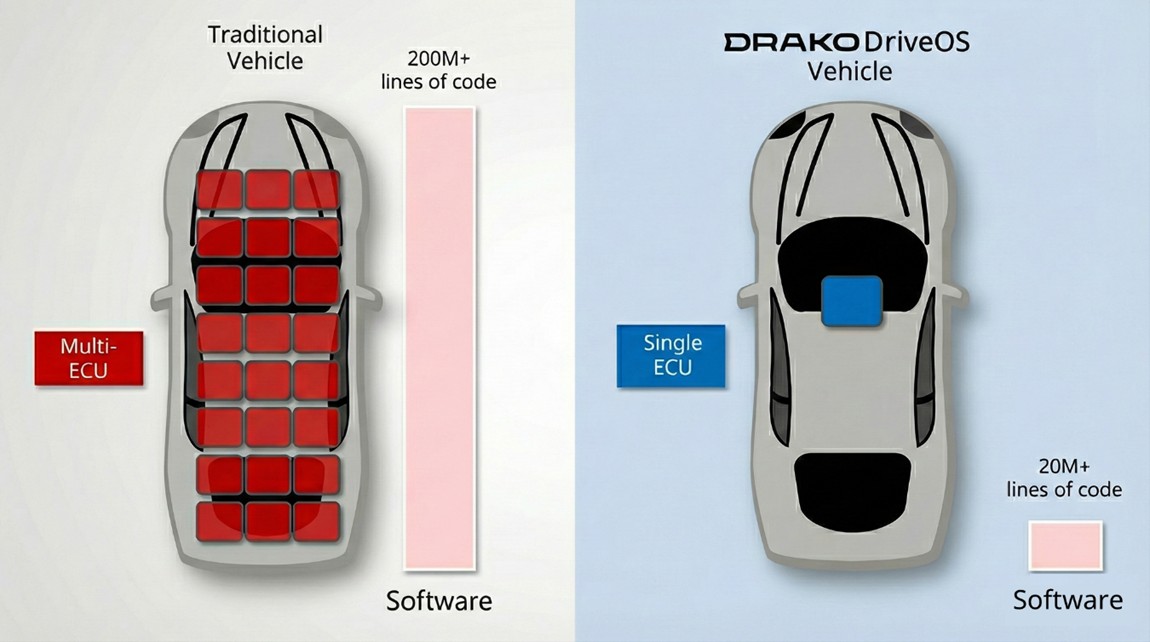

Drako DriveOS™ unifies control across all vehicle domains—from powertrain to cockpit to ADAS & AI — on a single ECU high-performance electrical/electronics vehicle architecture.

It eliminates the overhead of fragmented stacks, enabling faster integration, fewer ECUs, and dramatically shorter development cycles.

Proven in luxury performance vehicles — it’s engineered to streamline your next vehicle & fleet development, while delivering hard real-time predictability.

Proven Single-ECU Vehicle Architecture for Faster, Lower Cost Development

Unified Electronics & Software Operating System

Drako DriveOS is a unified electrical/electronics architecture, networking, and vehicle operating system that consolidates all core functions—across powertrain, ADAS & AI, infotainment, and more—onto a single platform.

Easy, Flexible Application Integration

OEM and third-party applications can be easily ported into DriveOS with minimal adaptation—no hypervisors, wrappers, or extensive rework required.

This architecture has been validated in Drako’s high-performance vehicles—and now enables faster, lower-cost development for OEMs bringing new platforms to market.

Once aligned with DriveOS APIs and execution model, ported modules run with the same real-time precision as Drako’s solution suite, including nanosecond-level scheduling and deterministic I/O.

Real-Time USB Stack — One Cable for Unified Networking, Device Control, Power Delivery

DriveOS extends its unified architecture into the communication layer by replacing fragmented vehicle networks—such as CAN, Ethernet, and FlexRay—with a single, real-time USB software stack. All domains and modules communicate over the same protocol and timing model, eliminating the need for bridging logic, gateway ECUs, or clock synchronization.

This approach simplifies hardware design and accelerates software integration. The result is faster module onboarding, lower integration cost, and a streamlined data path from sensor to compute to actuator.

Single USB stack eliminates automotive Ethernet complexity

DriveOS’s real-time USB stack delivers deterministic vehicle communication without the infrastructure overhead of automotive Ethernet.

DriveOS’s USB approach eliminates coordination layers. Critical control data is prioritized through the real-time USB stack, with deterministic scheduling built into the platform. Developers work with one protocol stack, one timing model, and one validation framework. There’s no clock synchronization to configure, no traffic shapers to program, no multi-device timing analysis.

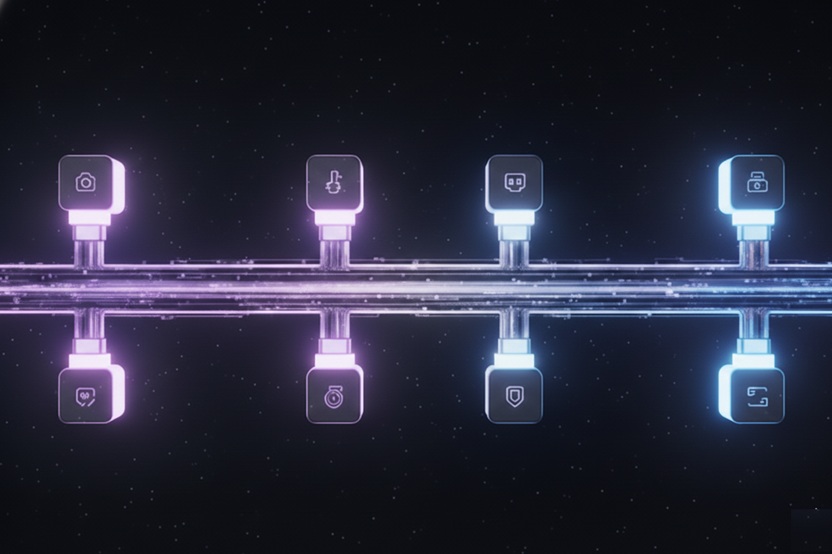

Digital harness — Plug-and-play extensibility throughout the vehicle lifecycle

Digital harness — Plug-and-play extensibility throughout the vehicle lifecycle

Drako’s digital harness technology, DigiHarness™, builds on the single USB cable backbone, replacing ECUs with virtual ECUs and plug-and-play physical interfaces. The extensibility lets manufacturers connect new devices without requiring any rewiring.

This plug-and-play architecture enables manufacturers to use one core harness across their product line and add modules as needed — using USB hubs for power, device control, and networking.

DigiHarness eliminates the constraints, complexity, and costs of fixed pin architectures, allowing OEMs to easily update their vehicles throughout the product lifecycle.

Real-Time, Predictable Performance Without Engineering Overhead

DriveOS delivers the speed and predictability needed for ADAS and AI, chassis control, and autonomy workloads—without relying on virtualization layers that can introduce timing variability or require complex mitigation to maintain timing and isolation.

Because the system behaves the same way every time, engineers don’t need to fine-tune latency paths or debug erratic performance. DriveOS supports high-end real-time workloads on shared hardware—with the simplicity and predictability smaller OEM teams need to move quickly.

Architectural Isolation for Mixed-Criticality & Fault Recovery

Vehicles contain both safety-critical and non-critical functions. DriveOS enforces domain-level isolation, so faults in infotainment, AI, or OTA modules remain contained and cannot impact critical control systems.

Because isolation is enforced at the architectural level, OEMs can target safety validation where it matters most—without having to recertify the entire software stack. This means new features or software updates can be rolled out quickly, without triggering revalidation of already-certified safety domains—cutting integration time from months to weeks.

The Drako single-ECU vehicle architecture delivers the isolation foundation required for functional safety, while enabling rapid, fault-tolerant behavior across all domains.

Runs on a Multicore PC — No Custom Silicon, No Vendor Lock-In

Drako DriveOS runs all vehicle domains—from safety-critical control to infotainment—on an off-the-shelf multicore processor. There’s no need for custom automotive silicon or domain-specific ECUs. This reduces component costs, simplifies the supply chain, and gives OEMs freedom to source hardware from multiple vendors.

By consolidating functionality on standard multicore hardware, DriveOS helps OEMs move faster, cut integration time, and scale their platforms without vendor lock-in or hardware redesigns.

This approach has been validated in advanced, production supercars. The same class of commercial off-the-shelf hardware has also been adopted in avionics, where fault isolation and deterministic behavior are critical. These real-world deployments demonstrate that safety, performance, and cost efficiency can coexist—without requiring custom silicon.

Hardware-Level Security Built into Single ECU Vehicle Architecture

Security is a growing concern for connected and software-defined vehicles. Many systems rely on layered software defenses—like access controls, hypervisors, or runtime firewalls—but these often share hardware resources, making them vulnerable to timing-based or cache-based side-channel attacks.

This secure-by-design architecture resists microarchitectural attacks without runtime patching, making it ideal for vehicles that support OTA updates, connected services, and mixed workloads on shared hardware.

Safety-Critical Architecture: ASIL D-Ready

DriveOS HyperSafety is architected to meet ASIL D—the highest safety classification under ISO 26262.

The architecture supports independent certification of individual domains, allowing OEMs to achieve ASIL D compliance for safety-critical subsystems while running lower-criticality functions on the same hardware. Integration time can be reduced from months to weeks because changes to non-safety-critical domains don’t trigger revalidation of already-certified safety functions.

OEM Payoff: What the Drako Platform Architecture Enables

Drako’s platform architecture gives OEMs a clean path to modernize vehicle systems without adding safety or security risk. By unifying control, autonomy, and infotainment on a single software stack, the electrical/electronics architecture eliminates legacy gateway logic and simplifies domain integration.

This translates to reduced wiring complexity, lower BOM costs, and easier servicing. OEMs can integrate Drako’s solutions for:

- Digital cockpit

- Control system development with reference implementations

- Autonomous driving & assistance

The same foundation proven in ultra-high-performance vehicles now scales efficiently to cost-sensitive platforms—offering real-time precision, proven security isolation, and modular safety validation in a single design-ready platform.